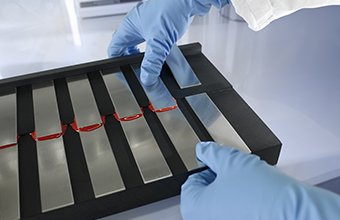

Innovative Solutions for Sealing, Casting, and Bonding

BY RAMPF ADVANCED POLYMERS

We have been developing and manufacturing reactive resin systems based on polyurethane, epoxy, silicone, and silane-modified polymers – for more than four decades.

Our products and solutions are used globally and in a wide range of industries – from automotive and electromobility, electrics/electronics, and white goods to aerospace, foundry, furniture, and mattresses.

We conserve resources and protect our environment, both in the development of our chemical products and in their manufacture and recycling.

Together with our customers and partners, we are working towards a successful and sustainable future.