Enclosure industry

Safely protected

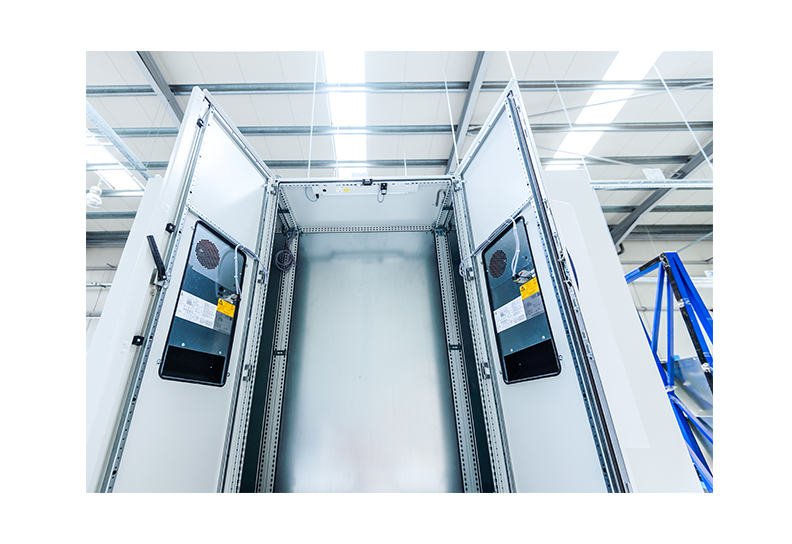

Electronic components and devices require reliable protection against moisture, chemicals, and environmental factors to ensure long-term functionality and user safety. Additionally, they must meet stringent tolerance compensation requirements.

Whether indoor or outdoor – RAMPF Advanced Polymers has the best sealing system for every application. The reactive casting resin systems exhibit high sealing quality (IP-tested), excellent aging resistance, low assembly forces, and optimal adhesion to stainless steel, aluminum, powder coating, and plastic.

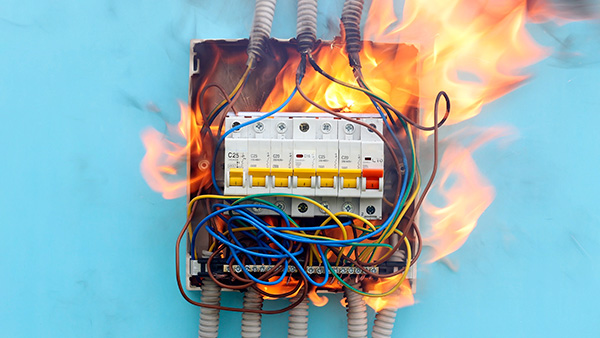

The product lines RAKU® PUR and RAKU® SIL enable two- and three-dimensional applications and meet the growing demands for flame-retardant materials according to UL 94 – ideal for areas with potential ignition sources.

Sealing systems from RAMPF Advanced Polymers are certified according to UL 50 and UL 50E, the globally recognized (including USA, Canada, and Mexico) standard for high-quality sealing solutions in control cabinets and electronic housings.

What WE offer you!

- Robust Housing Solutions – Reliability for indoor use, durability for outdoor use, resistant to environmental influences (UV, moisture, cold etc.)

- Perfect for Industrial Plants – High resistance to chemicals, dust, and mechanical loads

- Compliance with Highest Standards – Testing and listing in accordance with UL, NEMA, and ATEX

- Expertise & Innovative Strength – With decades of experience in customized sealing systems and the confidence of leading companies across diverse industries

- Quality & Standards – Highest product quality, customizable solutions, and certifications according to ISO 9001, ISO 14001, IATF 16949, and ISO 27001

- Sustainability & Responsibility – Environmentally conscious production and sustainable development as an integral part of our company philosophy

Reliable compensation of component tolerances while maintaining consistently high sealing quality

Hydrophobic integral skin provides superior waterproofing, making it suitable for both indoor and outdoor applications

Excellent resilience and aging resistance guarantee a long service life of the sealing foams

Application in a groove or directly on the flat surface of the component

Outstanding adhesion properties on a wide range of materials ensures strong bonds between foam gasket and component

Compliance with the highest fire protection standards