RAKU® TOOL: High-performance products for the foundry industry!

For pattern and core making

Reducing the CO2 footprint

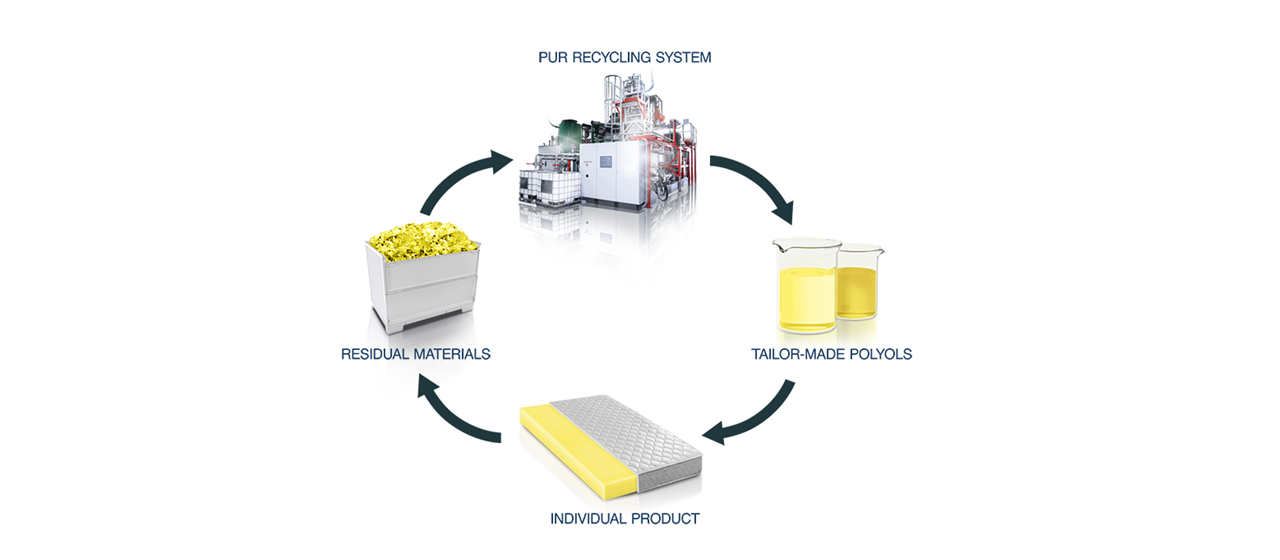

The majority of our foundry boards is eco-friendly. They contain up to 30% raw material components from chemical recycling.

The raw material components are obtained through chemical recycling of PET residues or by recycling our own production residues. Up to 50% of our production residues are recycled using a chemical recycling process developed by RAMPF.

Development & Production

The raw material components are developed and produced by RAMPF Advanced Polymers.

Alexander Ege

Our polyols are of a very high quality and have the properties required to produce high-performance board materials. With this approach, we live up to our responsibility as a sustainable company. That was the claim of our company founder Rudolf Rampf back in the 1990s.

VIDEO

In this video, Denny Föhn, Director of Business Center Tooling & Modeling at RAMPF Advanced Polymers, provides more information on the CO2 footprint, especially with regards to our board materials.