Chinese Engineers Utilize Vast Potential of RAMPF Mineral Casting

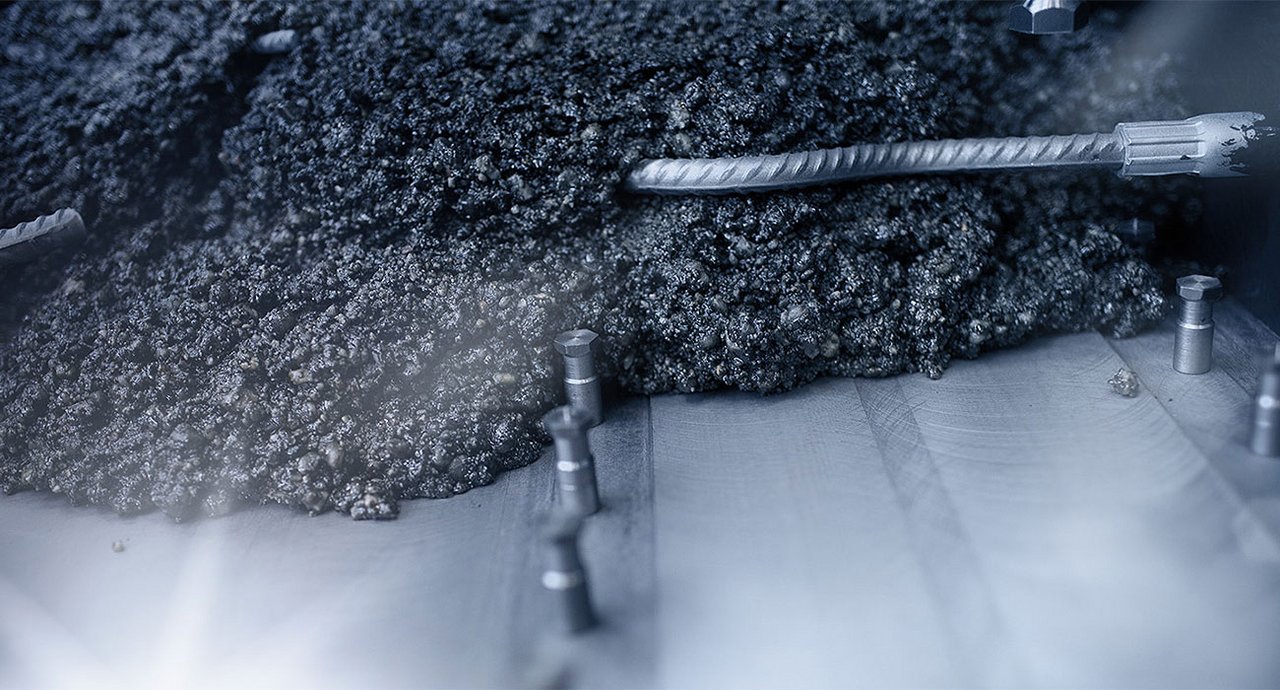

Unbeatable damping qualities, outstanding thermal stability, unparalleled design flexibility, energy-saving production – RAMPF is presenting its EPUMENT® mineral casting technology for high-performance machine beds and structural components at JM Qingdao International Machine Tool Exhibition 2024 – Hall W1 / Booth C55

Key facts

- 1. The stand-out benefits of EPUMENT® mineral casting are its outstanding damping qualities, extremely high thermal stability, and unparalleled design flexibility.

- 2. The material’s high degree of functional integration paves the way for developing intelligent machine beds for the digitization of manufacturing processes.

- 3. Small carbon footprint – compared to gray cast iron and steel, the manufacture of EPUMENT® mineral casting emits up to 4.5 times less CO2.

An increasing number of engineering companies in China are utilizing the vast potential of EPUMENT® mineral casting to manufacture machine beds and structural components in machine tool construction and the semi-conductor, laser, medical, and packaging industries, amongst others. The main benefits of RAMPF’s epoxy-based material:

- Outstanding damping qualities – the machine bed structure guarantees maximum dynamic stability in ultra-fast and high-precision production machinery; comparative measurements of logarithmic decrement as a damping parameter show that mineral casting has a material damping capacity that is eight to ten times greater than metal materials such as gray cast iron and welded constructions.

- Outstanding thermal stability – the material’s low thermal conductivity ensures a very slow response to short-term temperature influences; as a result, the minimal deformation of the frame ensures maximum machine accuracy.

- High degree of functional integration – the cold-casting process of EPUMENT® enables sensors and actuators to be directly integrated into the machine bed, making these so-called “intelligent machine beds” an important prerequisite for the digitization of manufacturing processes.

- Energy-saving production, environmentally friendly disposal– thanks to cold casting and an extremely high casting accuracy, up to 75 percent primary energy is saved compared to gray cast iron, and CO2 emissions are 4.5 times lower; RAMPF mineral casting can be recycled as normal construction waste for fillers or soil stabilization.

RAMPF (Nantong) provides its customers with a holistic service offering, including material-specific design and engineering, production, assembly, and the construction of customized multi-axis moving systems and basic machinery.