Maximum Protection of Luminaires – Sealing and Casting Technology from RAMPF

RAMPF Group, Inc. is presenting its high-performance sealing and casting systems as well as automated dispensing technology for the cost-effective, fast, and flexible manufacture of luminaires used in correctional facilities at the American Correctional Association (ACA) Congress of Correction from August 15 to 18 in Nashville, TN – Booth 433.

Key facts

- RAMPF offers first-class contract manufacturing services for the sealing, casting, and bonding of luminaires used in correctional facilities.

- Material and machine from a single source – the company specializes both in reactive plastic systems and the corresponding mixing and dispensing technology.

- At ACA Congress of Correction 2024, RAMPF is showcasing two high-performance rigid casting polyurethanes with outstanding mechanical and chemical properties.

To guarantee the safety, performance, and durability of luminaires, they must be effectively protected from dust, heat, humidity, water, chemicals, and physical manipulation. For this, leading lighting manufacturers use two-component reactive plastic systems.

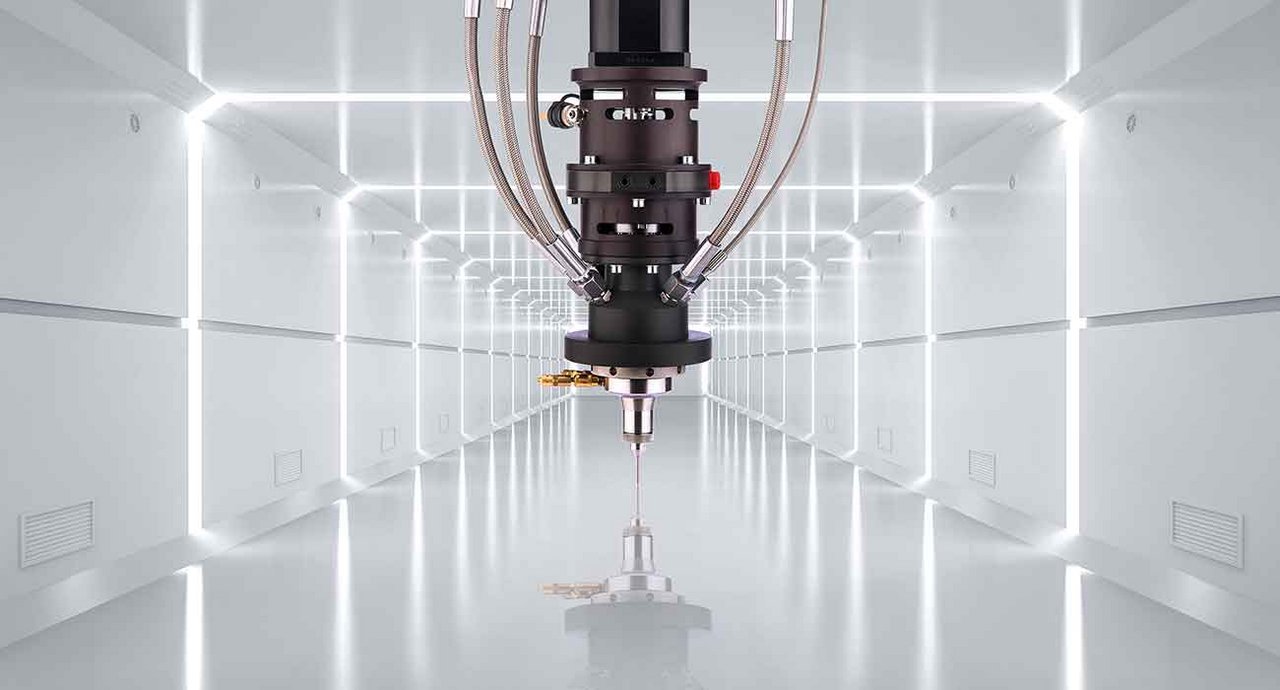

To achieve best results, both the plastics systems and the corresponding mixing and dispensing processes must be perfectly aligned. This is a given for RAMPF, as the company is a market-leading specialist for

- Reactive resin systems based on polyurethane and silicone, including liquid, thixotropic, and rigid sealing and casting systems.

- Automated production systems with integrated dispensing technology for sealing, casting, and bonding reactive resin systems.

Gordon Winter, US Operations Manager at RAMPF Group, Inc.:

This chemical and processing technology know-how is brought together in our cost-effective, fast, flexible, and reliable contract manufacturing service for the sealing, casting, and bonding of luminaires. We provide our customers with a holistic solution, encompassing customized plastic systems and automated mixing and dispensing technology.

Product highlight: Rigid casting polyurethanes

At this year’s ACA Congress of Correction, RAMPF is presenting two high-performance polyurethane casting systems that guarantee the maximum, long-term protection of luminaires:

RAKU® TOOL InnoClearTM OC-5246-3 – aliphatic, rigid polyurethane system

- Excellent physical properties after PC cure

- Outstanding light diffusion properties

- Free of mercury, MOCA, and TDI

- Specially formulated for castings into either tin or platinum silicone molds

RAKU® TOOL InnoClearTM OC-5320 – water-clear, rigid polyurethane system

- Excellent physical properties after RT cure

- Outstanding optical clarity

- Free of mercury, MOCA, and TDI

- Mixed material can be cast into either tin or platinum silicone molds