RAMPF’s High-Performance Potting Materials Drive Growth in India's EV Market

Tailor-made for maximum performance and service life – RAMPF is presenting its encompassing portfolio of electro casting resins and gap fillers for electric vehicle (EV) components at MatDispens in Delhi, India, from September 11 to 13 – Hall H7 / Booth E21

Key facts

- Electro casting resins and gap fillers from German-based company RAMPF Advanced Polymers ensure optimum functionality and maximum durability of electrical/electronic components.

- Electro casting resin systems provide reliable and efficient protection against chemical substances and environmental influences such as heat, cold, and moisture.

- The company’s gap filler portfolio ensures optimal heat dissipation, safeguarding sensitive components from overheating to enhance drive performance and extend vehicle lifespan.

RAMPF Electro Casting Resins

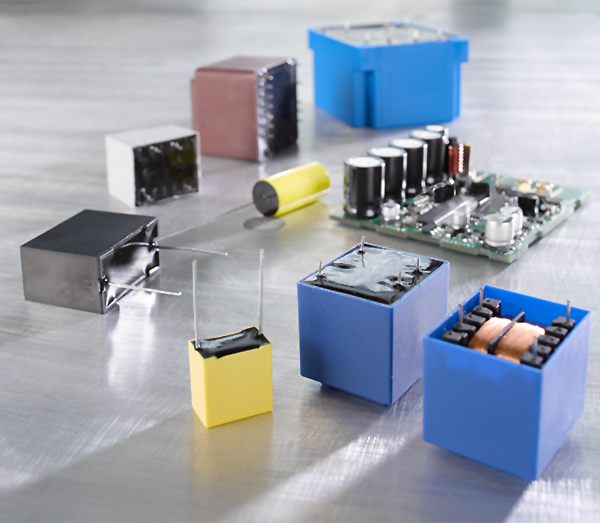

One- and two-component electro casting resins based on polyurethane (RAKU® PUR), epoxy (RAKU® POX), and silicone (RAKU® SIL) reliably and efficiently protect sensitive electrical/electronic components, batteries, motors, power electronics, sensors, and transformers from chemical substances and environmental influences such as heat, cold, and moisture. RAMPF Advanced Polymers’ potting systems are listed by leading manufacturers in the automotive and electronics industries, amongst others.

RAMPF Gap Fillers

Gap fillers based on silicone (RAKU® SIL) are used in components in the battery and power electronics industries to close gaps between components and heat-dissipating surfaces. The high thermal conductivity of the thermal interface materials is increased by thinner adhesive joints and good wetting. RAMPF’s low density gap filler portfolio exhibits outstanding continuous temperature resistance, aging resistance, and thixotropic properties for easy processing.

RAMPF Sealing Systems

RAMPF Advanced Polymers also offers liquid to highly thixotropic and compact gaskets for the long-term protection from moisture, dust, and chemicals. The polyurethane (RAKU® PUR) and silicone (RAKU® SIL) systems are used, amongst others, for sealing battery covers, brake and taillights, chargers, loudspeakers, fuse boxes, and door modules.

Think global, act local

Senthil Kumar, Business Development Manager at RAMPF Advanced Polymers:

The Indian market is rapidly expanding, offering tremendous opportunities for our company, particularly in the EV and power electronics industries. With our encompassing expertise in both resin systems and their precise, fast, and cost-efficient dispensing, we offer customers holistic solutions for their manufacturing processes. We look forward to engaging with the world's top manufacturing experts at MatDispens and exploring exciting new projects.

Visit RAMPF Advanced Polymers at MatDispens in Delhi from September 11 to 13 – Hall H7 / Booth E21!