Sculpting Made Easy Peasy

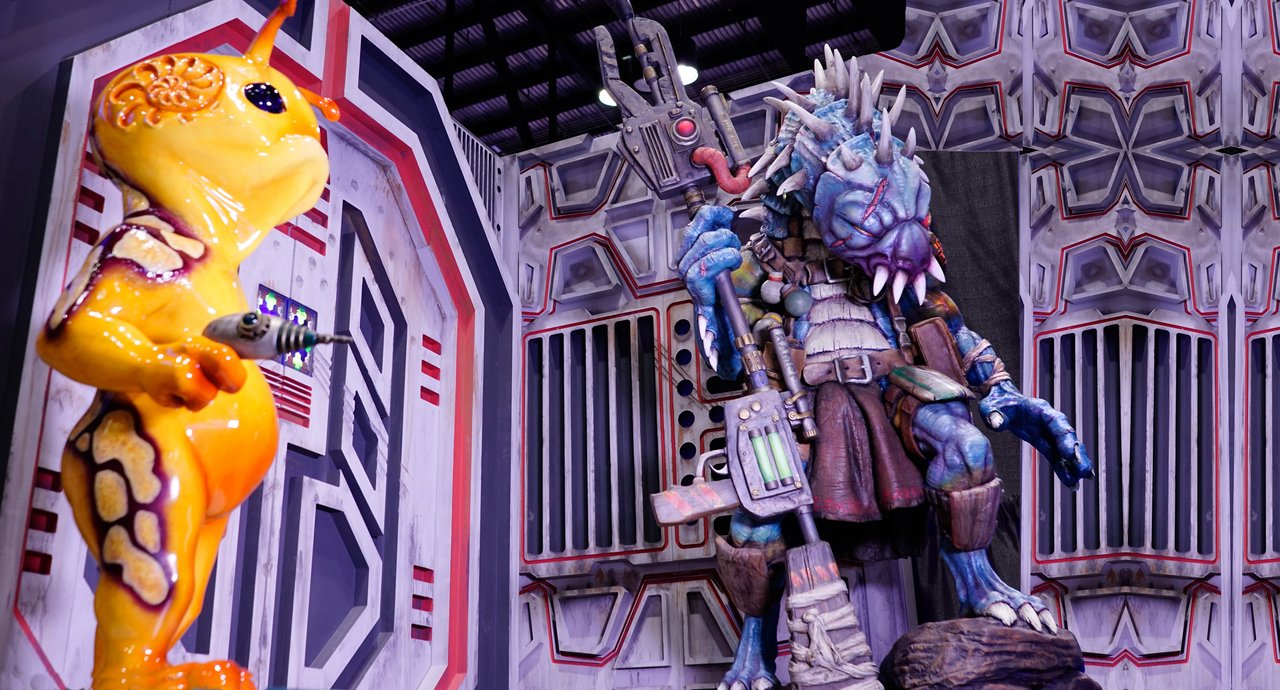

Sculpting made easy peasy – with RAMPF’s brand-new RAKU® TOOL EZ-PZ putty epoxies for the sculpting and architectural industries. The innovative line of E84 Class A flame-rated systems is meticulously engineered to meet the highest standards of performance, safety, and ease of use, allowing artists, architects, and builders to bring their most ambitious projects to life. The EZ-PZ portfolio will be officially presented at the IAAPA trade show in Orlando, FL, from November 19 to 22 – Booth 2078.

Key Messages

- RAMPF’s brand-new RAKU® TOOL EZ-PZ putty epoxies for the sculpting and architectural industries meet the highest standards of performance, safety, and ease of use and will be officially presented at the IAAPA trade show in Orlando, FL.

- The E84 Class A flame-rated systems are available in four distinct versions, designed to cater to specific needs and applications: Lightweight, Standard Weight, Castable, and Flexible.

- Further trade show highlights for the themed environments industry – Low- & high-density tooling boards, versatile silicones for mold making and props, and high-performance liquid polyurethane systems.

The RAKU® TOOL EZ-PZ portfolio developed by RAMPF offers four distinct epoxy systems, each designed to cater to specific needs and applications:

- EZ-PZ Light: This lightweight epoxy offers exceptional ease of sculpting and stamping without sagging on vertical surfaces. It is non-sticky, making it ideal for detailed work that requires a steady hand.

- EZ-PZ Standard: Ideal for larger surface areas, this standard-weight epoxy has a spreadable consistency that enables both stamping and sculpting, making it a versatile choice for various applications.

- EZ-PZ Castable: Often used as a hard coat or top layer for decorative elements, this castable epoxy can be molded and is the product of choice when an E84 Class A rating is required for architectural purposes.

- EZ-PZ Flexible: The newest addition to the EZ-PZ family, this flexible epoxy mixes easily and accepts textures and stamps exceptionally well, providing excellent versatility for various creative applications.

Marianne Harris, Sales Manager at RAMPF Group, Inc.:

Whether you are sculpting intricate designs or coating large architectural elements, our epoxy systems are designed to help create with ease and precision, all while meeting the highest quality and safety standards. We are excited to see the incredible creations that artists and designers will craft with our new EZ-PZ product range. The design possibilities are limitless!

At this year’s IAAPA trade show, RAMPF is also showcasing the following high-tech fabrication materials for the themed environment industry:

Low- & High-Density Tooling Boards

Low-density options (4–20 lbs) are ideal for hand sculpting and CNC cutting

Superior surface finish reduces need for extensive finishing, saving time and effort

High-density options (28–106 lbs) for precision and durability in demanding tooling applications

1- and 2-component adhesives specifically tailored to the boards

Tailored for diverse applications, including mold making and crafting small props

Designed for maximum precision and versatility

Available in both tin- and platinum-based cures

Wide range of Shore hardness values

Translucent options for enhanced visibility

Comprehensive range of customizable silicone pigments

Available options include ASTM/UL flame-rated materials, clear castings, and 2-part expandable foams

Systems cover various casting methods, such as mold-pouring, roto-casting, hard coating, and sprayable applications

Maximum flexibility for unique production requirements

Custom formulations for specific project needs