Tailor-Made for Maximum Performance & Service Life: Electro Casting Resins & Gap Fillers from RAMPF

RAMPF Advanced Polymers is presenting high-performance electro casting resins and gap fillers for the electrical and electronics industry at PCIM Europe from June 11 to 13 in Nuremberg – Hall 6 / Booth 6-427.

Key Facts

- 1. Electro casting resins and gap fillers from RAMPF Advanced Polymers ensure optimum functionality and maximum durability of electrical/electronic components.

- 2. Electro casting resin systems provide reliable and efficient protection against chemical substances and environmental influences such as heat, cold, and moisture.

- 3. Gap fillers ensure optimum heat dissipation and protect sensitive components from overheating.

RAMPF Electro casting resins

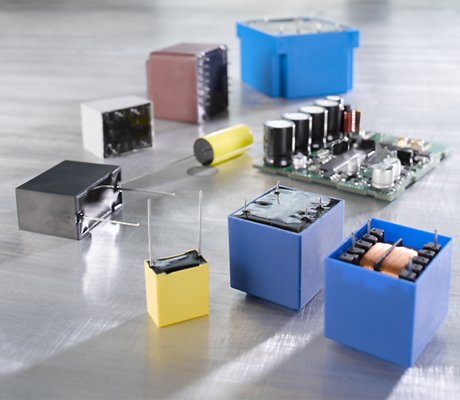

One- and two-component electro casting resins reliably and efficiently protect sensitive electrical/electronic components, batteries, motors, power electronics, sensors, and transformers from chemical substances and environmental influences such as heat, cold, and moisture.

The potting systems are listed by leading manufacturers in the automotive and electronics industries, among others.

RAKU® PUR Polyurethane electro casting resins

Typical applications: Casting of circuit boards, capacitors, inverters, sensors, inductors, EMC filters, and many more.

Benefits:

- Wide Shore hardness range (20A - 90D)

- Easy adjustment of reactivity

- Low shrinkage

- Low exothermicity

- Fast processing

- High shock resistance

- Good adhesion to plastics

RAKU® POX Epoxy electro casting resins

Typical applications: Casting of capacitors, motors, transformers, circuit boards, control devices, and many more.

Benefits:

- High mechanical strength and good adhesion to metal

- Very good chemical resistance

- Very good impregnation

- High abrasion resistance

RAKU® SIL Silicone electro casting resins

Typical applications: Casting of printed circuit boards, sensors, power electronics, chargers, control units, sensors, batteries, and many more.

Benefits:

- Very good temperature resistance

- Consistent properties over the entire application temperature range

- Good aging resistance

- High thermal conductivity

- Good crack resistance

- Very good chemical resistance

- High UV and weather resistance

- Minimal SVHC levels

Gap fillers (thermal pastes) based on silicone are primarily used in components in the power electronics and battery industries to close gaps between the components and the heat-dissipating surface. The high thermal conductivity of the thermal interface materials is further increased by thinner adhesive joints and good wetting.

RAKU® SIL Silicone gap filler

Typical applications: Power electronics, automotive electronic components, computers, peripherals, and many more

Benefits:

- High continuous temperature resistance

- Good aging resistance

- Low density

- Good thixotropic properties for ideal processing

- Low SVHC values

- Optimal heat dissipation for efficient performance and long service life of components