Maximum Power – RAMPF Electro Casting Resins

RAMPF Advanced Polymers is presenting high-performance electro casting resins based on polyurethane, epoxy, and silicone for the electrical and electronics industry at PCIM Europe in Nuremberg from May 6 to 8 – Hall 6 / Booth 6-427.

Key Facts

- Electro casting resins from RAMPF Advanced Polymers ensure optimal functionality and maximum lifespan of electrical and electronic components.

- The high-performance potting systems based on polyurethane, epoxy, and silicone are listed with leading manufacturers in the automotive and electronics industries.

- Product highlight at PCIM 2025: RAKU® PUR 21-2380-3 with outstanding thermal conductivity, low water absorption, and good hydrolysis resistance.

Electro Casting Resins – Maximum performance based on polyurethane, epoxy, silicone

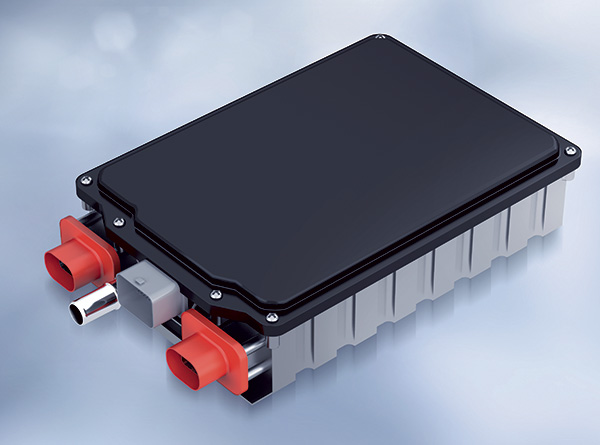

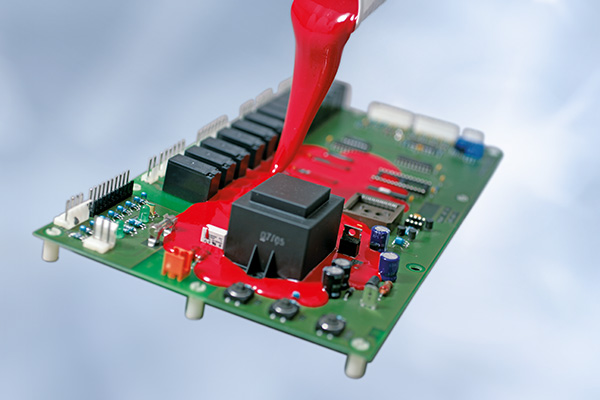

One- and two-component electro casting resins reliably and efficiently protect sensitive electrical/electronic components, batteries, motors, power electronics, sensors, and transformers from chemical substances and environmental influences such as heat, cold, and moisture. The potting systems are listed with leading manufacturers in the automotive and electronics industries, among others.

RAKU® PUR Polyurethane electro casting resins

Typical applications: Casting circuit boards, capacitors, inverters, sensors, inductors, EMC filters, and many more.

Benefits:

- Wide Shore hardness range (20A - 90D)

- Easy adjustment of reactivity

- Low shrinkage

- Low exothermicity

- Fast processing

- High shock resistance

- Good adhesion to plastics

RAKU® POX Epoxy electro casting resins

Typical applications: Casting capacitors, motors, transformers, circuit boards, control devices, and many more.

Benefits:

- High mechanical strength and good adhesion to metal

- Very good chemical resistance

- Very good impregnation

- High abrasion resistance

RAKU® SIL Silicone electro casting resins

Typical applications: Casting printed circuit boards, sensors, power electronics, chargers, control units, sensors, batteries, and many more.

Benefits:

- Very good temperature resistance

- Consistent properties over entire application temperature range

- Good aging resistance

- High thermal conductivity

- Good crack resistance

- Very good chemical resistance

- High UV and weather resistance

- Minimal SVHC levels

Product highlight at PCIM 2025: RAKU® PUR 21-2380-3

RAMPF’s flame retardant, RoHS-compliant polyurethane system impresses with its excellent thermal conductivity of 1.9 W/m-K, low water absorption, good hydrolysis resistance, and good flow properties.

Thanks to non-abrasive fillers, RAKU® PUR 21-2380-3 can be processed with standard two-component mixing and dispensing systems.