Vertical Integration – For the Benefit of the Customer

Discover how RAMPF Composite Solutions is making composite manufacturing faster and more cost-effective by combining expertise from multiple specialized fields.

To begin with, it must be said that vertical integration is not a sure-fire recipe for success. The notion of a company controlling the majority – if not all – of its value-creation chain can only work if it has encompassing specialist knowledge in each stage of the supply chain.

If this is the case, however, this in-house strategy can serve to streamline the speed and efficiency of the product’s journey from sketch into the hands of the customer.

In the competitive landscape of composite manufacturing, RAMPF Composite Solutions stands out as a leader by harnessing expertise from multiple specialized fields. This strategy has enabled the company to offer complete in-house product solutions for the aerospace, defense, industrial, medical, high-end consumer, and green transportation industries.

Higher profitability and higher customer satisfaction

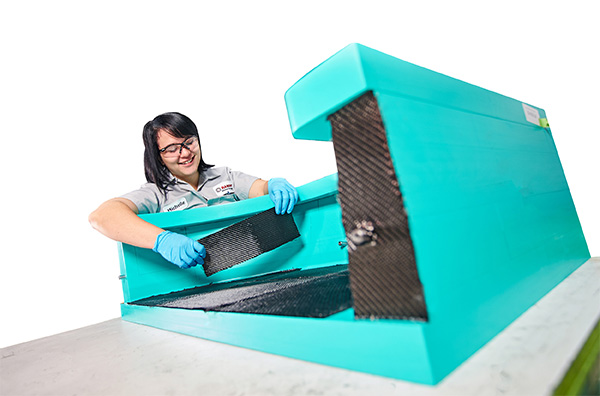

Vertical integration at RAMPF Composite Solutions means that everything from initial design and engineering to final manufacturing and quality assurance is handled internally.

The company’s wide range of competencies and technologies encompasses, amongst others:

- Advanced manufacturing techniques: From Vacuum Assisted Resin Transfer Molding (VARTM) and vacuum infusion to compression molding and hand layup, RAMPF utilizes the best methods to suit each project’s needs.

- Tailored Fiber Placement (TFP): This technology optimizes fiber placement to enhance the strength and stiffness of composite parts while minimizing weight.

- Painting and coatings: RAMPF offers painting and coating in-house, eliminating the need to send parts out to separate facilities.

- Metal plating and assembly: RAMPF offers metal plating with copper and electroless nickel as well as complete sub-assembly services, including hardware integration.

This approach offers several key benefits:

- Streamlined processes: By managing the entire production process in-house, RAMPF streamlines operations, reduces lead times, and eliminates the delays often associated with outsourcing.

- Cost efficiency: Vertical integration reduces the costs associated with external suppliers and sub-contractors; RAMPF can better control expenses and pass on these savings to its customers.

- Enhanced quality control: With all production stages under one roof, RAMPF maintains stringent quality control throughout the manufacturing process, ensuring high standards and consistency from start to finish.

Leveraging the synergies of a global group of companies

RAMPF Composite Solutions works hand-in-hand with the resin and tooling specialists at RAMPF Advanced Polymers to create a fully integrated process that enhances competitiveness, efficiency, and the ability to deliver top-quality composite solutions. This integration allows for faster production times, cost-effective solutions, and superior quality, meeting the stringent demands of industries such as aerospace and medical technology.

Larry Fitzgerald, CEO of RAMPF Composite Solutions:

Being part of the RAMPF Group gives us the opportunity to leverage the synergy effects of our chemical, tooling, and composite engineering experts. This creates a more efficient, reliable, and competitive operation, ultimately leading to higher profitability and higher customer satisfaction.

Putting theory into practice

A prime example of RAMPF’s successful implementation of vertical integration is the collaboration with a leading manufacturer of flight simulators.

By utilizing the combined capabilities of RAMPF Composite Solutions and the tooling solutions specialists at RAMPF Advanced Polymers, the time-to-market for the production of essential simulator components were halved.

- Initial Design: Using advanced 3D modeling and Finite Element Analysis (FEA), RAMPF Composite Solutions’ engineers designed the components with precision.

- Tooling and prototyping: The master patterns were created using RAMPF Advanced Polymers’ high-quality RAKU® TOOL board materials, known for their excellent surface finish and dimensional stability.

- Manufacturing: Using VARTM and cost-optimized resin infusion processes, the final composite parts were produced fast and efficiently.

- Quality Assurance: Throughout the process, RAMPF’s built-in quality assurance systems ensured each part met stringent industry standards.