High-quality, sustainable &

cost-effective

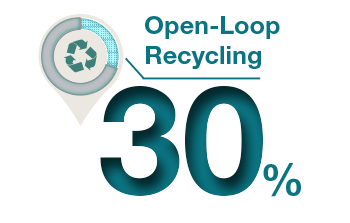

Recycling Polyols

RAMPF Advanced Polymers specializes in chemical and process engineering solutions for the manufacture of high-quality recycling polyols.

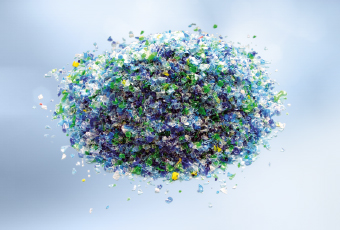

We are pioneers in chemical recycling: For more than three decades, we have been developing and producing tailored polyols from recycled PUR/PIR residues and PET/PSA in multifunctional plants using solvolysis (glycolysis, acidolysis, and polyolysis).

The basic polyols obtained from this process are reintegrated by our customers into their production. This creates a cycle that delivers both environmental and economic benefits.

RAMPF bio polyols made from renewable raw materials complete our sustainable product portfolio.

Your benefits

- High quality of recycling and bio polyols

- Former product characteristics retained in new cross-linking

- Significant reduction of CO2 footprint compared to primary polyols

- Reduced disposal costs

- Highly efficient saving of resources

- Environmental protection via raw material recycling

- No reliance on dwindling petrochemical raw materials