Vibration-damping & highest precision

Machine beds and components

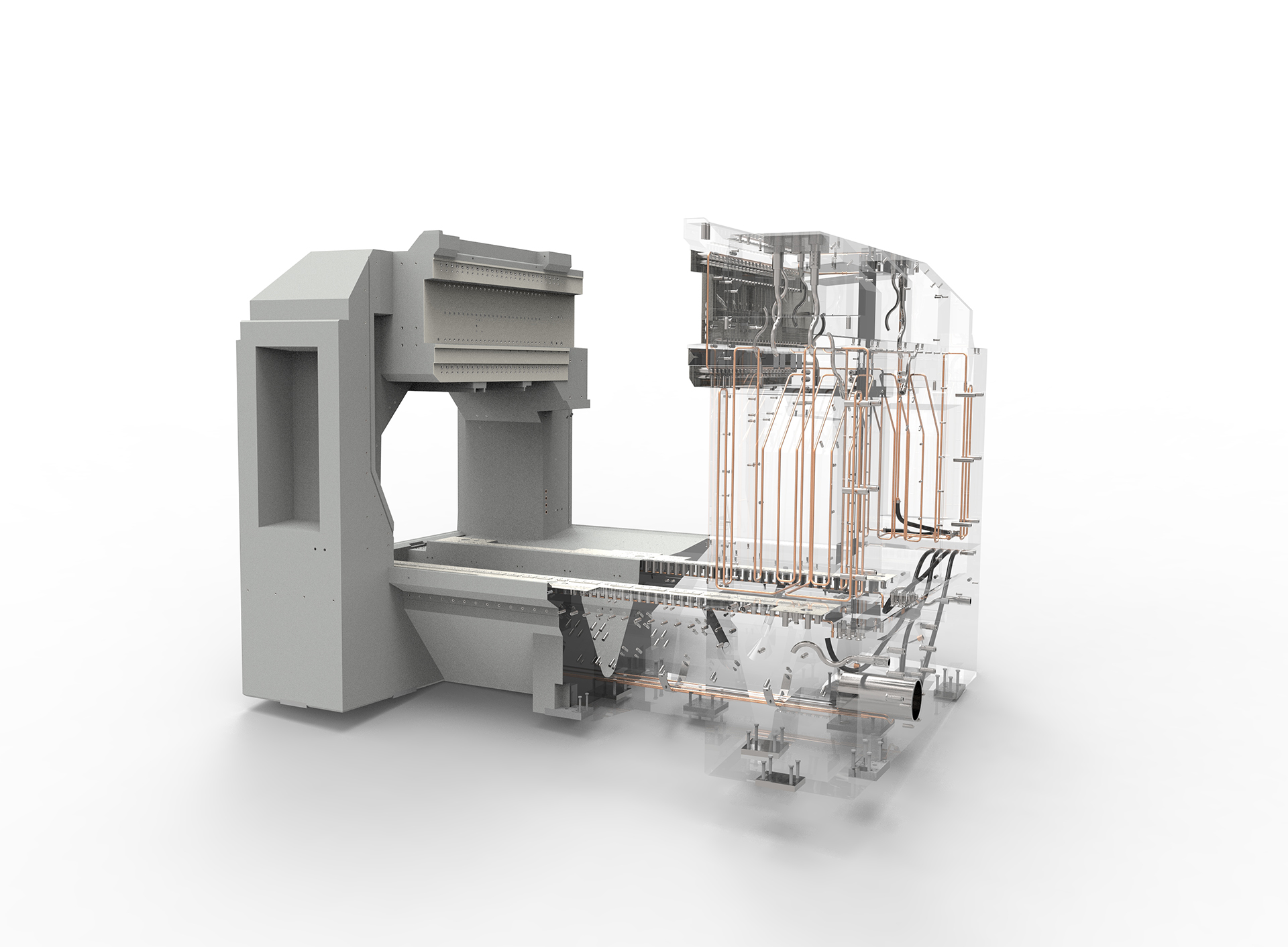

RAMPF Machine Systems develops and produces innovative machine beds and machine bed components using high-performance materials.

Alternative materials such as mineral casting (polymer concrete/EPUMENT) and ultra-high-performance concrete (UHPC/EPUDUR) offer outstanding damping properties, low thermal conductivity, high isotropy, homogeneity, and resistance to media. They also allow for flexible shaping, chipless molding, and the use of innovative adhesive technologies.

Furthermore, by integrating sensors and actuators into machine beds and machine bed components made of alternative materials, so-called "intelligent machine structures" are manufactured. These include, among others, sensors for temperature measurements to detect interfering heat, as well as corresponding tempering lines to counteract this interfering heat.

Mineral casting developed and produced by RAMPF for machine beds and machine bed components stands out due to its resource-efficient production, as well as environmentally friendly disposal and recycling:

- EPUMENT mineral casting and EPUDUR ultra-high-performance concrete are cold-cast into molds made of wood, steel, or plastic. As a result, up to 4.5 times less primary energy is consumed in production compared to other materials used for machine beds and machine bed components.

- The high casting precision, combined with RAMPF’s in-house high-precision replication technology, eliminates the need to transport machine beds and machine bed components to external processors and reduces or avoids the use of machining tools.

- EPUMENT mineral casting and EPUDUR ultra-high-performance concrete consist of more than 90 percent naturally occurring minerals and stones, combined with an epoxy resin-based binder (EPUMENT) or a cement-based binder (EPUDUR). These materials can therefore be disposed of as standard construction waste.

- The crushing of mineral casting and ultra-high-performance concrete components into high-grade chippings using large-scale shredders, as well as the separation of embedded metal parts, has been successfully tested. High-grade chippings from mineral casting can be reused as recycled construction material in road and path construction, industrial building projects, landfill surface sealing, or landscaping.

Material and technology

![[Translate to English international (en):] [Translate to English international (en):]](/fileadmin/_processed_/f/c/csm_teaserbox-mineralguss_8f56a98009.jpg)

Mineral casting (EPUMENT®)

EPUMENT® mineral casting is a high-tech material that is perfect for the primary machine bed functions, such as precisely securing the geometric position of the individual machine elements, and the static, dynamic, thermal, and acoustic absorption of forces and moments.

Ultra-high performance concrete (EPUDUR)

EPUDUR is an ultra-high performance concrete (UHPC) based on the latest generation of premium cements. It has been further developed from Mikrodur technology using nano-structured synthetic silica.

![[Translate to English international (en):] [Translate to English international (en):]](/fileadmin/_processed_/8/a/csm_EpucretKIT_000175B_Raum_64869a7485.jpg)

Hard stone (EPUSTONE)

Industrially mined hard stone (commonly known as granite) has been used for several decades for measuring plates, straightness and angle standards, and machine bed components for measuring and high-precision production machinery. Hard stone is an isotropic, homogeneous material that follows Hooke’s law and can be analyzed using linear-elastic FEM modeling.

![[Translate to English international (en):] [Translate to English international (en):]](/fileadmin/_processed_/2/c/csm_Epufill-gefuellt_5759d8c3d2.jpg)

Composite constructions (EPUFILL)

For four decades, cavities in steel or cast iron machine beds and machine bed components have been filled with epoxy resin-bonded mineral casting. Initially often used to subsequently improve dynamic performance, this has since become a process in its own right.